Joyful Noise was done in collaboration with the New England Conservatory of Music at the Boston Center for the Arts Cyclorama. In collaboration with a lighting designer, I worked as assistant manager of a six person team to create an environmental installation that would divide the 23,000 sq foot venue into smaller zones, and reflect the spirit of the fundraisering event whose title the piece is named after.

Initial explorations were done with scale models and photography. Different tensile forms were experimented with and spacial configurations tried. Modeling helped communicate and iterate with the client, and ultimately led to our final floor plan.

Fabrication of the Ribbon Wall was complicated given the compound angles and variable curves. Because there was no plain right angle to be found on the piece, customized ways of measuring had to be developed, leading to the creation of innumerable jigs that allowed for accurate assembly.

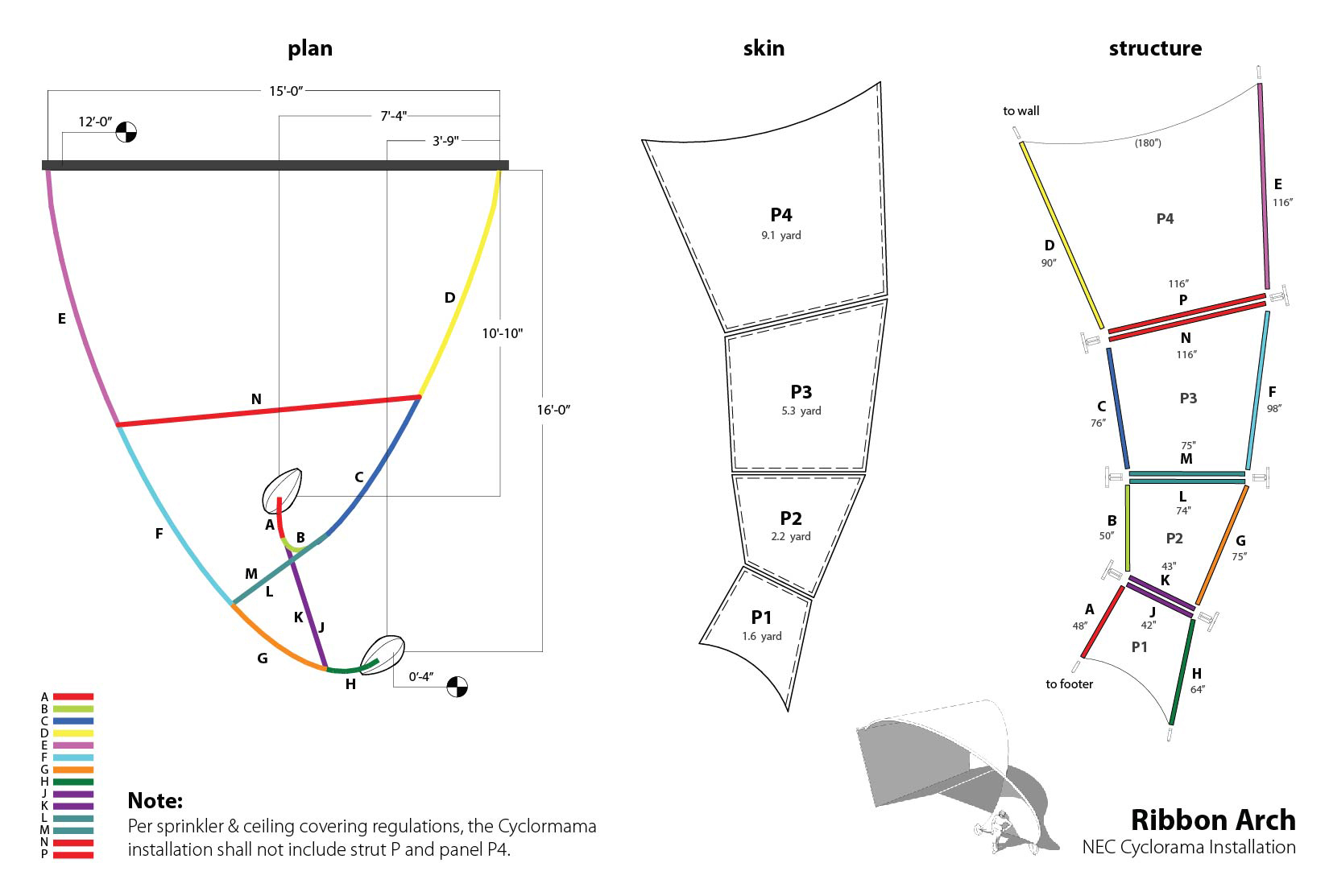

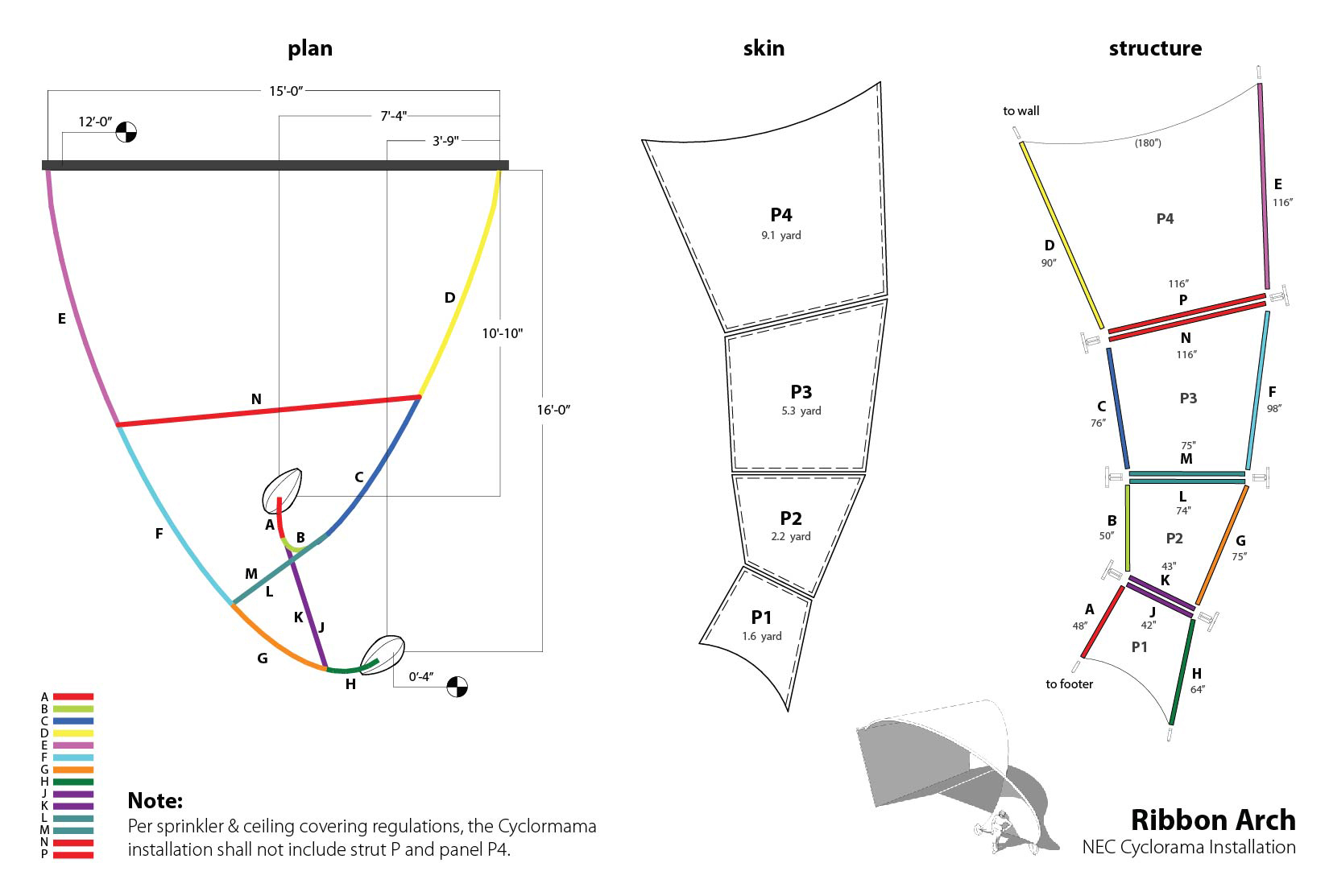

All diagrams done with Tagore Hernandez.

Extensive diagraming was necessary to make both production and installation go smoothly. As installation was confined to just a few hours prior to the event, large groups of volunteers would be assisting. It was paramount that the instructions we provided were clear, concise and as simple as possible so that these large teams could proceed as efficiently as possible.

All diagrams done with Tagore Hernandez.