The Story of Stuff is an original work by choreographer Betsi Graves and performed by her dance company, Urbanity Dance. Inspired by Annie Leonard’s video of the same title, The Story of Stuff deals with concepts of greed and materialistic values in our contemporary society. Graves created fascinating characters to represent our internal propensities.

In talks with Ms. Graves, lead designer Leah Johnstone-Mosher and collaborator Severin Lafrance came up with two dynamic props that were able to support the concept of the Story of Stuff and were interactive enough to influence the choreography.

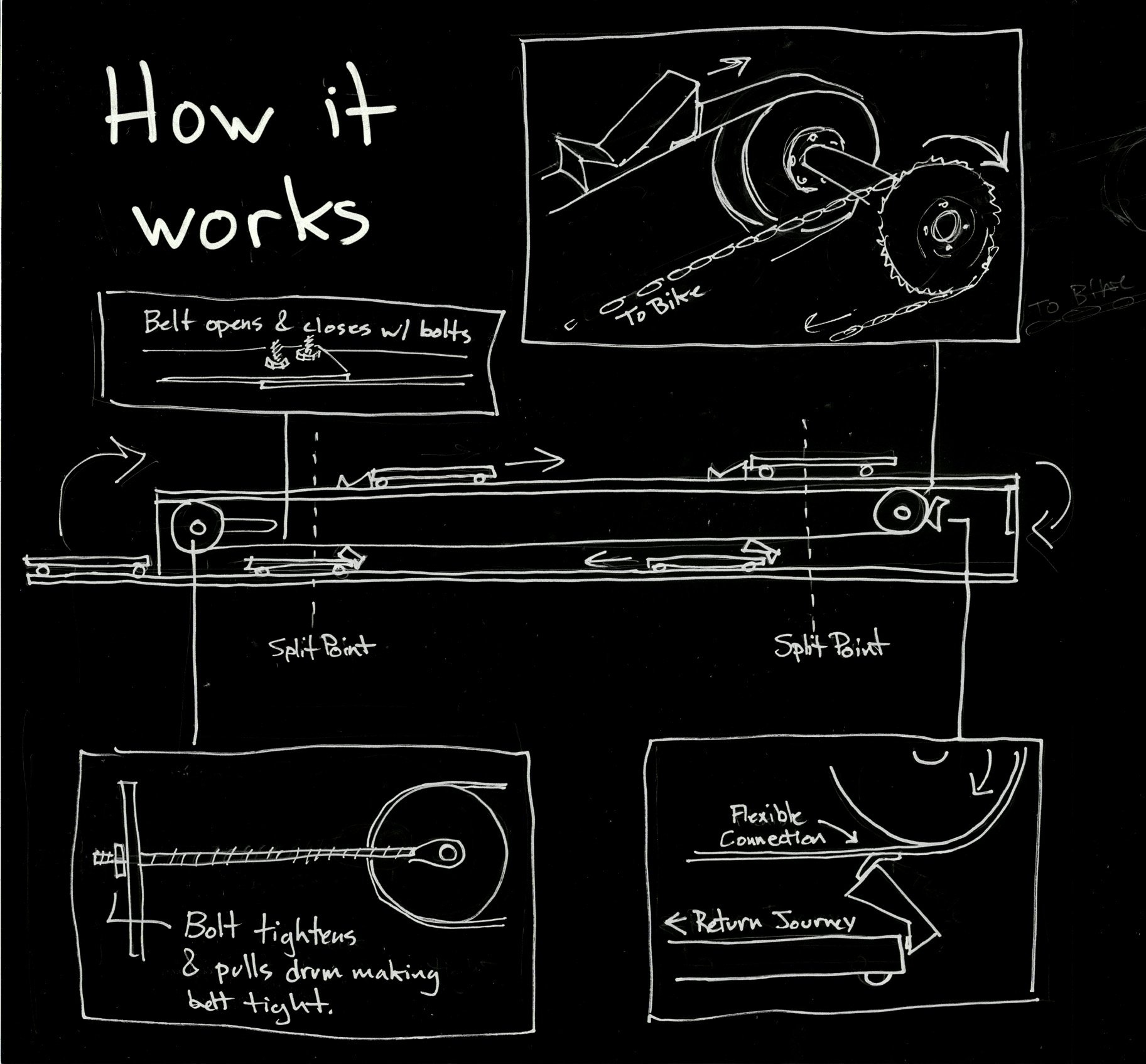

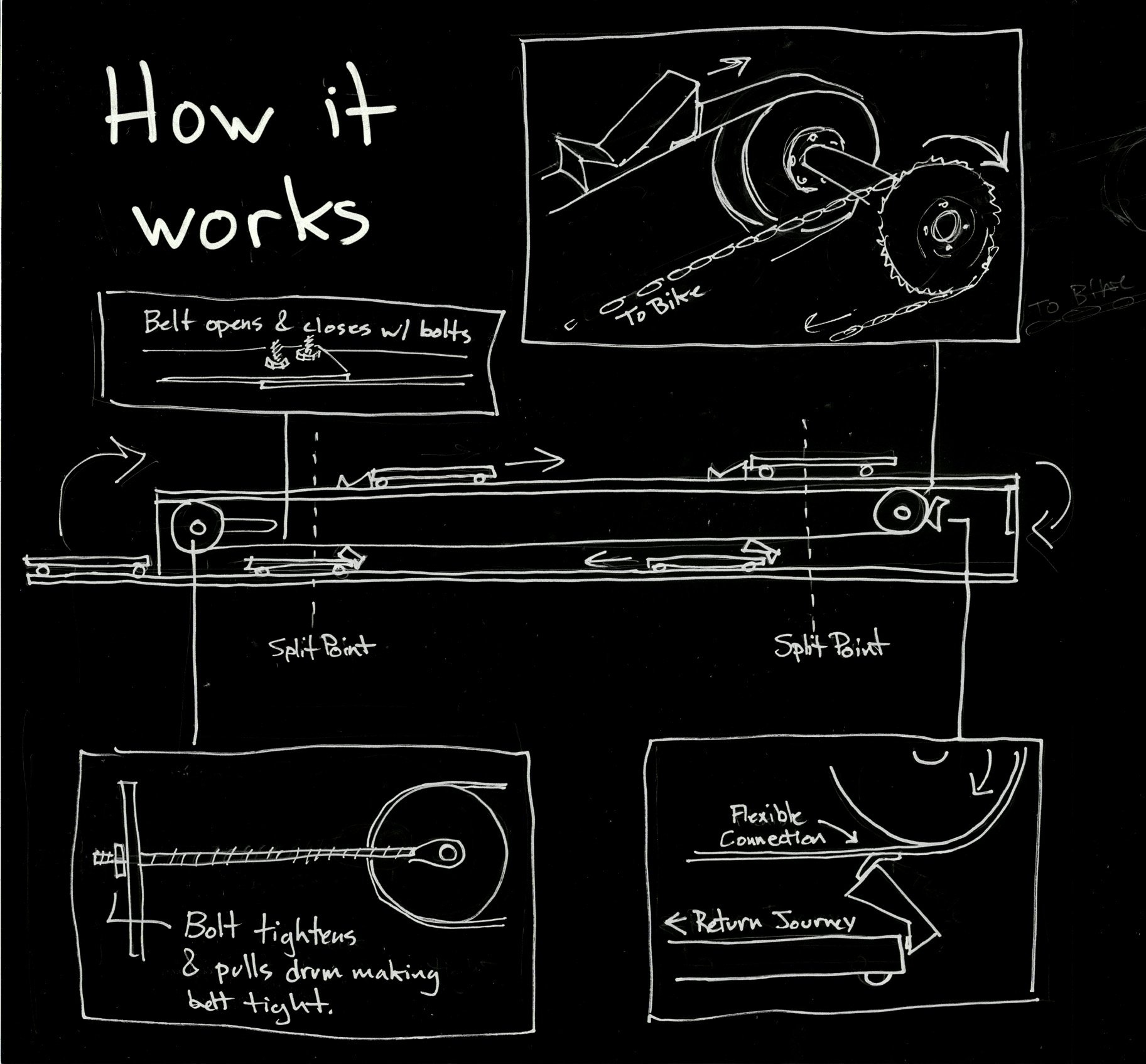

The first prop, an exercise bike driven conveyor belt engaged with Graves’ characters, the “factobots.” The piece illustrated the self-manufacture of these mechanical beings.

The design and fabrication was a particular challenge as the Story of Stuff was performed in two very different venues. One was a small black box theater with constrained entryways, so the piece had to be modular in order to enter. The second theater was a large proscenium style theater where props needed to have the presence to fill a stage of that scale.

The second prop was a human scale hamster wheel, referencing the endless and fruitless nature of consumerist cultures.

The wheel was constructed of plywood, steel conduit, and a series of casters that allowed it to rotate in place and stay justified horizontally, ensuring the stability of the wheel as it moved. In one venue, the wheel had to rotate, but stay in place, making the base necessary. When moving to the second venue, however, we discovered that it could traverse the stage quite smoothly. The choreography was amended to exploit this newly discovered feature.

Again because of threshold constraints, the wheel had to be able to break in two and be reassembled quickly. This was accomplished by using overlapping layers of plywood that required a total of 8 screws to be reassembled.